Smart Fabrics

"What makes smart fabrics revolutionary is that they have the ability to do many things that traditional fabrics cannot, including communicate, transform, conduct energy and even grow." This is a quote from Rebeccah Pailes-Friedman, who is a professor at Pratt with a research focus on developing wearable technology and smart textiles.

Enhancing textiles can be viewed through different lens. Enhancements can be aesthetic, or performance boosting, or durability boosting.

Aesthetic - Performance - Durability

Aesthetic means making it look good, distinct, stylish, enhancing it's visual appearance.

Performance refers to the performance of the person wearing the smart fabric while they do some task. Wearing the fabric makes you perform some task better.

Durability refers to the physical properties of the fabric itself. It's strength, longevity, ability to stretch, ability to withstand environmental conditions, etc. Can the fabric withstand Maui's tough for materials environmental conditions like hot sun, wet humidity, insidious mold without falling apart. Or can the smart cloth handle the conditions of space if you happen to be NASA.

You could try to tackle any and all of these enhancements without throwing electrical circuitry into the mix. So viewing a fabric like you would a composite material, improving the characteristics of the fabric by combining different materials (threads) together to make a composite material (woven textile).

Of course once you throw conductive threads and electrical circuitry into the mix, things can get even more interesting. Building sensors and potentially computational widgets for said sensors into the fabric itself can lead to all kinds of new enhancements.

And you don't have to limit yourself to just electronics, you can throw optical components in as well. Maybe carbon nano-tubes? Spider silk? You can be creative with what gets blended in there to hopefully synergistically lead to the enhancements you desire in the fabric.

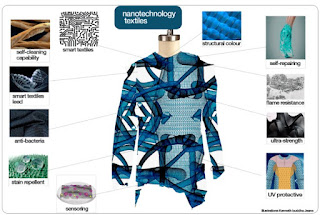

Here's an overview of Smart Textiles, predicted to be a $130 billion dollar market by 2025. They put smart textiles into 3 different categories, Passive, Active, and Ultra.

Passive smart fabrics just hold sensors in place somewhere within the fabric. An example would be a shirt that tells it's wearer that they slouching.

Active are smart fabrics that hold both sensors and actuators, so they can sense their local environment while also modifying it in some way at the same time. An example would be a shirt that heats or cools it's wearer to keep them at some optimal temperature.

Ultra smart fabrics utilize some aspect(s) associated with the physical construction of the fabric to directly build a sensor. And potentially to build actuators as well.

They also distinguish between Connected smart fabrics vs Nano (nanotechnology) smart fabrics.

Connected means garments embedded with digital technology.

Nano means that they are using nanotechnology to give materials new properties.

Project Jacquard

Google has a project called Jacquard, that 'weaves new digital experiences into the things you love' (pun). Which seems to refer to taking current digital experiences you use on your cell phone (listen to music, get reminders, take a photo) and letting you do these kinds of things by interacting with smart fabric you are wearing in some way.

The smart fabrics used in Google Jacquard based products have Jacquard Threads woven into them. they interact with micro-electronics and intelligent software. Jacquard Threads use conductive metal alloy fibers that are woven along with natural and/or synthetic fibers to create the smart fabric.

MIT Smart Fabrics Initiatives

Researchers at MIT have embedded high speed optoelectronic semiconductor devices within fibers that can then be woven like conventional textiles. Their ultimate goal is to create a new kind of fabric computer. They also want to build machine learning algorithms directly into smart fabrics. Here's some more information on their approach to advanced fabrics that can potentially do computation.

Other MIT researchers have embedded bacteria into fabrics to help ventilate garments. Or fabric keyboards built with conductive fabric.

MIT researchers feel that woven circuitry currently being contemplated (smart fabrics with threads that let you build semiconductor circuitry directly in the fabric) have the same Moore's Law growth potential that integrated circuits have displayed.

Caveat

There is some controversy about the naming terminology we've been throwing around. E-textile (electronic textile), smart textile, smart fabric, fibertronics, nanotechnology textile, etc. I'm trying to cover the reasons why people feel a need for distinct naming conventions here, because i think that's the important part to understand. So my apologies if i offend anyone with my loose usage of the terminology.

There is some controversy about the naming terminology we've been throwing around. E-textile (electronic textile), smart textile, smart fabric, fibertronics, nanotechnology textile, etc. I'm trying to cover the reasons why people feel a need for distinct naming conventions here, because i think that's the important part to understand. So my apologies if i offend anyone with my loose usage of the terminology.

How Do You Make Them

In an ideal world, you would go to the SmartFabric Store to pick up whatever smart fabric you were interested in. Maybe someday. But for now, unless you are interested in a fairly narrow set of products, you are probably going to be custom manufacturing your desired smart fabric.

Looms

Textiles are manufactured using looms. And they come in all shapes and sizes. The basic purpose of any loom is to hold the warp threads under tension to facilitate the interweaving of the weft threads. Warp and weft threads are fancy ways of saying longitudinal and transverse threads, or vertical and horizontal threads if you want to get really simple.

People have been documented weaving fabric with looms for well over 6000 years (probably longer). So the technology is very old. But just because it has been around forever doesn't mean we can't make it better. It probably was considered a high technology item when it was first invented. And further developments in technology seem to find their way into loom design when they occur throughout history.

Waterpower and then electrical engines drove powered looms since the late 1700s. Computational technology found it's way into looms with the development of the Jacquard loom in the early 1800s. A Jacquard loom is controlled by a series of punch cards, which allow for the automated execution of complex pattern designs in the woven textile weaved by powered or hand cranked looms. The Jacquard loom is the direct predecessor of the computer punched card readers we all grew up to love at the dawn of digital computers. And now you know why Google called their smart fabric initiative Project Jacquard.

Digital Looms

Old style Jacquard looms probably count as digital looms, since they are based on executing punch cards, so they are really a computational device in some sense. But nowadays you can buy commercial digital Jacquard looms that give you individual software programable control over every thread in a textile.

Digital Weaving Norway makes a beast of a machine, the TC-2 Jacquard loom. The TC-2 has been used to prototype a wide variety of different smart fabrics.

AVL Loom makes the Jacq3G.

Here's a great hands on comparison article that takes a look at both the TC-3 and the Jacq3G.

And why limit yourself to 2 dimensions when weaving anyway. Here's a very cool design for a digital 3-D weaving loom developed by Nigerian American designer Oluwaseyi Sosanya.

Surely we can add deep learning neural nets to digital weaving. Since it apparently makes everything better. Get to work students.

Hand Operated Looms

People have been making textiles the old fashioned manual loom way for a long time. If you ever travel to Indonesia you will at some point be dragged somewhere and shown that they are still making rugs that way today.

And you can make a custom smart fabric the old fashioned way as well. While incorporating digital technology to assist. Fabric artist Pamela Liou has built an open source Jacquard loom that mixes digital tech with hand weaving.

It seems like looms are one of mankind's oldest technologies. Whose roots lie all the way back in the Neolithic age, but whose applications and implementation continue to be innovated even today. Smart fabrics and enhanced textiles are just the latest chapter in this continuing story.

Comments

Post a Comment